News

Latest Insights

Latest Updates and Conferences

DirectSens and MetAGE To Work Together On Developing Early Type 2 Diabetes Diagnostic

Klosterneuburg, Austria, 01 July, 2025 – Austrian biosensing company, DirectSens, is proud to announce the inking of a collaboration agreement with MetAGE, an Austrian research consortium whose work centres on healthy aging. The work will focus on validating DirectSens’ XpressGT, a test for 2-hydroxybutyrate in blood that is being developed

DirectSens Strengthens Commitment to Workplace Health and Well-Being

VIENNA, Austria – January 22nd, 2025 – DirectSens is proud to announce that it has been awarded the BGF Gütesiegel for its sustained commitment to workplace health promotion. This accolade highlights companies that prioritize the well-being and health of their employees. Over the past year, the company has implemented a

DirectSens’ Market-Leading LactoSens® BioSensor Technology acquired by Kerry Group P.L.C.

VIENNA. Austria – October 29, 2024 — DirectSens, a pioneer in next generation biosensor technology, announces the acquisition of its LactoSens® technology by Kerry Group, a global leader in taste and nutrition. The acquisition of LactoSens® reflects DirectSens’ success in developing cutting-edge biosensor solutions and represents a move by Kerry

Technology

End-to-End Biosensor Solutions

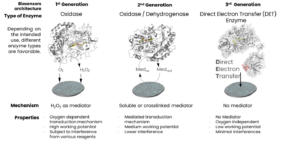

End-to-End Biosensor Solutions with Advanced Enzyme Technology At DirectSens, a full end-to-end solution for biosensor manufacturing is applied, where the entire process—from enzyme discovery to large-scale production—remains in-house. Advanced fermentation technology and bioinformatics are applied to optimize enzymes for modern sensor architectures. Enzyme production is scaled through precision fermentation to

Next Generation Biosensor Technology

The DirectSens Story DirectSens, an Austrian biotechnology company, has been at the forefront of biosensor innovation since its founding in 2013. Established with the mission of translating scientific research into practical solutions, DirectSens specializes in developing next-generation biosensors, focusing on creating enzymes tailored for specific applications. The company successfully launched

The core of every biosensor is an enzyme

Why enzyms play a curcial role in biosensors Biosensors are powerful analytical devices that detect and measure specific analytes, revolutionizing fields like healthcare and environmental monitoring. Since the first commercial biosensor was introduced in the 1970s, these devices have saved millions of lives (Clark et al., 1962). However, the enzymes

Products

DirectSens’ Market-Leading LactoSens® BioSensor Technology acquired by Kerry Group P.L.C.

VIENNA. Austria – October 29, 2024 — DirectSens, a pioneer in next generation biosensor technology, announces the acquisition of its LactoSens® technology by Kerry Group, a global leader in taste and nutrition. The acquisition of LactoSens® reflects DirectSens’ success in developing cutting-edge biosensor solutions and represents a move by Kerry

A Breakthrough for Women’s Health: DirectSens Launches XpressGT to Combat Gestational Diabetes and More

XpressGT provides accurate measurement of levels of 2-hydroxybutyrate (2-HB) found in venous blood.

DRRR proficiency testing confirmed excellent performance of LactoSens®R

DRRR proficiency testing confirmed excellent performance of LactoSens®R Accuracy, precision and reliability are the key success factors of LactoSens®. The latest DRRR proficiency testing confirmed this claim, again! We are periodically challenging LactoSens® in external proficiency tests (see Independent proficiency testing showed excellent results for LactoSens® for more results). In the latest DRRR proficiency test two UHT

DirectSens and MetAGE To Work Together On Developing Early Type 2 Diabetes Diagnostic

DirectSens Strengthens Commitment to Workplace Health and Well-Being

DirectSens’ Market-Leading LactoSens® BioSensor Technology acquired by Kerry Group P.L.C.